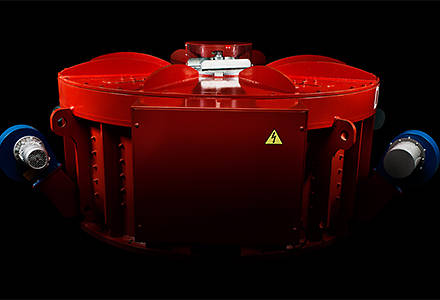

LEITNER DirectDrive is an exclusive, in-house drive solution developed by LEITNER Ropeways. This gearless drive system uses an electric, low-rpm synchronous motor that is directly linked to the bullwheel assembly.

With this design, there are far fewer moving parts than conventional drive systems. In short, there are just three moving components — the rotor and two bearings — resulting in many advantages:

- Lower Noise Levels

- No Engine Oil

- Reduced Maintenance Costs

- Lower Operating Costs (no gearbox inspection)

- Greater Efficiency

- High Reliability

- DirectDrive frame can be easily moved for adjustments to elongated ropes

In particular, low noise levels means that drive stations can be located next to and integrated with sensitive lands uses such as residential and commercial properties with minimal interference. This is especially important in complex and dense urban environments where quiet operations are necessary.

Lower operating costs is also a critical factor as urban cable transit lines often operate for more than the usual 10 hours per day experienced in ski resort settings.

Since 1999 DirectDrive systems are now found in nearly two dozen countries and have been installed in 55 ropeways and 310 wind generators.

For more information about this special drive solution and how LEITNER can assist you with your urban cable car project, click here.

Materials on this page are paid for. The Gondola Project (including its parent companies and its team of writers and contributors) does not explicitly or implicitly endorse third parties in exchange for advertising. Advertising does not influence editorial content, products, or services offered on The Gondola Project.