This is a guest post by Billy Beasley.

For many years, some critics of urban gondolas have argued that they won’t work in dense city centers due to the lack of space to build terminals. These stations, especially for larger lift types like the 3S or Aerial Tram require larger buildings to house the important machinery that power them.

Even more space is required on systems where the operator wants to take the cabins off the line nightly and keep them in a storage building to prevent wear and tear. Thus, one question becomes how to minimize and conserve space for urban gondolas in situations where land is in short supply. For this first article of a 2-part series, we will examine two unique and innovative case examples.

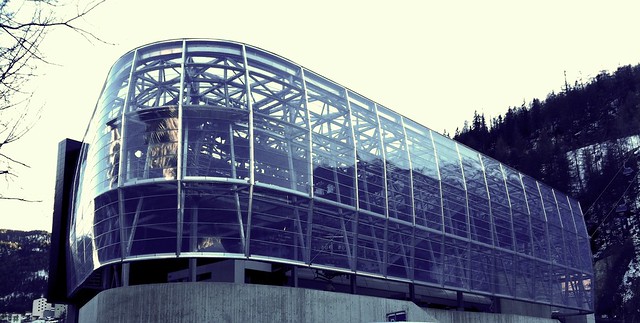

Solden Ski Resort – Gaislachkoglbahn (Austria)

Check out this Doppelmayr installation in Austria at the well-known Solden Ski Resort named Gaislachkoglbahn. This system is designed with two segments: the first section consists of a monocable gondola while the second section has a 3S tricable gondola.

Typically there would four terminals for the lift but in this instance, Solden only built 3 stations (map of transfer station). The top terminal of the 8-passenger gondola is combined with the bottom terminal of the 3S system. With this configuration, it saves money and space as two stations are built as one single building.

The two cable lifts also feature incredibly innovative cabin parking systems. The monocable’s lower segment parks the cabins above the actual lift terminal itself and when the operator is ready to start the cable car, the cabins descend on a series of rails down to the terminal where they join the line.

The 3S segment also features an innovative cabin management system located in the bottom terminal of the lift (which remind you, is also the top station of the lower segment). The cabins enter the bottom station but a set of the in-terminal sheaves rotates and transfers the cabin from the line to a series of rails. From here, it transfers the cabin to the correct spot in the parking area. The parking area itself is inside the station, where the lift maze starts for loading the 3S gondola. With this design, the entire system manages to save a significant amount of space as potentially six buildings for the system (four stations, two cabin parking buildings) has been effectively reduced to three.

This would be helpful for an urban gondola system that wants to utilize cabin parking but doesn’t have a tremendous amount of space to put the cabins when they are not on the line.

Keystone Mountain (Colorado) – Outpost Gondola and River Run Gondola

Keystone Mountain in Colorado used cabin parking for their two gondolas in an before they built their new gondola but they did it in an interesting fashion. The bottom floor of the Outpost Gondola (the top was the lift station itself) was a sprawling cabin parking facility for both the Outpost Gondola and the nearby River Run Gondola.

Check out Skilifts.org for some great pictures and walkthrough of this design!

Lift maintenance would transfer the cabins from the line of the River Run Gondola to the cabin parking facility where the cabins from the Outpost Gondola were also being stored. From here, maintenance crews could work on the grips, clean the cabins, and store the cabins properly for both lifts in one convenient location. This is especially impressive when you consider that the lifts were built by two different manufacturers – the River Run Gondola by Von Roll and the Outpost Gondola by Doppelmayr (keep in mind, this was before Doppelmayr purchased Von Roll and both companies had separate grip designs at the time).

Therefore, two different rails and two different storage pods needed to be built because the Von Roll cabins couldn’t go on the Doppelmayr rails and vice versa. There were two separate control systems but maintenance could do typical work on the cabins in one big facility.

This design could be helpful on urban gondola systems that are built with two different lift types or on ones that add another section to an existing system of a different model.

In the next article we will examine systems in Nevada, Vermont and Colorado. Stay tuned!

8 Comments

How important is station parking? I would imagine except in areas with extreme winds, in urban environments it may make more sense to just leave them outside. Is the wear and tear on the cable? Or are they just afraid of some rain and snow?

Wear and tear on cable is not a critical consideration for short term scenarios.

That being said, station parking is important for several other reasons. Maintenance is much easier when performed indoors in an area that is sheltered from inclement weather and is adequately lit, with tools and spare parts in close proximity.

Environmental wear and tear is also an important factor, especially in harsher climates. Resorts will remove cabins from their lifts over the summer in order to prevent them from getting bleached by sun, etc. The same principle applies here.

And from an image perspective, station parking is far more professional than parking cabins outside.

But the fight is always for real estate. And so there is always pressure to minimize the station footprint. I would expect any significant urban system built now to have, at the very least, indoor parking for at least some of the cabins.

But surely an urban system will be in full operation when the sun is out. And I’m sure they can have some space indoors for overnight maintenance without having a large parking area.

For small systems with a limited number of cabins you can store them within the terminals. But this is definitely not possible with larger systems where a separate garage is needed.

I really like the design for Keystone Mountain though. Integrating the two garages into one is definitely a space saving technique that would be useful in urban scenarios.

It is certainly true that you can get away with minimal parking. I suppose I can re-state my general point as: if you have the real estate and the money, then build some nice facilities. As Nick discusses, the parking footprint can be much smaller than most people realize.

But where space and budget are limited, yes, you can minimize the footprint and keep more cabins outside or on the line.

The urban systems I am seeing now have increasingly nice maintenance facilities/parking areas. Which to me corresponds with the increasing sophistication of the industry and it’s responsiveness to urban demands.

Thanks Sean, that’s good to hear. I’m fine with projects choosing to have parking – if nothing else it would make for less clutter in the night sky (ok, the 3am to 5am night sky). But the tradeoff with lost urban space and increase costs might be a hindrance to making these systems work financially and catch on in other cities. Instead of planners being told “you need to have this amount of space for parking” (because that’s the way we always do it), I want it presented as an option.

Conversely, a minimalist approach is to have just enough parking to house the number of cabins that would normally be in the turnaround areas of the drive, intermediate and return stations. This keeps most of the cabins on the rope out of the stations, but ensures that cabins are not left out in the stations where the could be subjected to vandalism, etc. You could then develop a rotating maintenance plan that ensured that each defined set of cabins was parked during a defined interval, whereupon it could be washed, maintained, etc.

Cabins garage is not really a technical problem , it’s just that part of mountain lift owners were used for decades to fixed-grip lifts that stayed outside all season, and still some objects to the costs related…

An automatized cabin garage could be placed literally everywhere , I’m waiting to see the first plant with an lift-transporter like those used in automatic warehouses .