Two weeks ago I travelled to Medellin, Colombia and Caracas, Venezuela to tour five of the most important CPT systems in the world. This is Part 6 where I discuss the technological innovations of the Caracas Metocable. Image by Steven Dale.

Like the Medellin Metrocable, the Caracas Metrocable is a MDG system, the most basic of aerial Cable Propelled Transit technologies. It is fully-integrated into the local Metro system, has a maximum operating speed of 18 km/hr, a capacity of 3,000 pphpd and is 1.8 km long. Vehicles can carry 8 sitters and 2 standees. The system has 2 terminals and 3 intermediary stations; a total of 5 stations. Unlike the Medellin systems, which were built by the French-Italian consortium of Poma-Leitner, the Caracas Metrocable was built by the Austrian-Swiss partnership of Doppelmayr/Garaventa.

The most important aspect of the Caracas Metrocable is its alignment. The Caracas Metrocable’s alignment includes two extreme 90 degree turns. That this was the first aerial cable system in known history to implement a 90 degree turn is impressive, that the designers had the guts to attempt two 90 degree turns is all the more so. With this single act, the cable transit industry has demonstrated their ability to adapt, innovate and improve upon their technology within the public transit market.

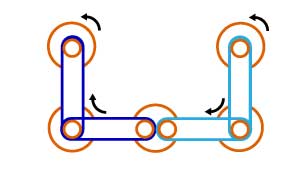

What’s more, engineers did not utilize a separate drive wheel at each angle station as is common in most corner-turning applications. Instead, engineers used a single, passive deflection bullwheel at the two 90 degree stations, dramatically reducing complexity, size and cost of the system. Only at the middle station is a second drive wheel utilized. This, in essence, means that the Caracas Metrocable is made up of two separate lines where vehicles switch automatically from one line to the second at the middle station.

A graphical representation of the Caracas Metrocable system. Notice how the system is made up of two separate lines (represented by two different shades of blue). If one line fails, vehicles can be re-routed back onto the original line. Image by Steven Dale.

Additionally, a mechanism was designed into the middle station that allows operators to divert vehicles such that they do not automatically switch onto the new line, returning instead from whence they came. This configuration creates enormous additional benefit from an operations perspective. In the even that either of the two lines were to experience mechanical difficulties, the second of the two lines would be able to continue operations.

This simple feature debunks the common (but provably misinformed) opinion that with cable technology when one part of the system goes down, the whole system goes down.

A passive deflection wheel at angle stations allow vehicles to make sharp, 90 degree turns. Image by Steven Dale.

Further features add to the Metrocable's appeal: Two way intercoms are located in each vehicle to assist with safety and emergency situations. Image by Steven Dale.

Sylish wooden benches in each vehicle are a charmingly casual (though somewhat Spartan) method of dealing with seating. Image by Steven Dale.

1 Comment