Last week’s post about six common uses for steel cables generated significant conversation and questions about the cables themselves. One question that was not asked, however, was how a company goes about splicing the two ends of a cable into one continuous loop.

I’m told this is one of the most impressive aspects of a cable system’s installation and is something I, myself have never witnessed. Only a handful of people worldwide are licensed to do this incredibly specialized operation. This multi-day operation involves a team of individuals untwisting tens of metres of steel cable and then re-twisting the two ends together at regular intervals in order to complete one single complete loop.

It is also this section of cable that is the most vulnerable to damage, thus the specialized nature of the operation.

For a great insight into this, check out Lift Wold’s cable splicing photo essay to see a cable splice, step-by-step.

Pretty impressive stuff.

4 Comments

I don’t think anything is welded…the loose strand ends (called lacings in the photo essay) are just tucked inside the core of the rope (in place of the plastic core the exists there normally)…friction takes care of the rest.

BC,

As I’ve never witnessed a cable splice, I’ll defer…

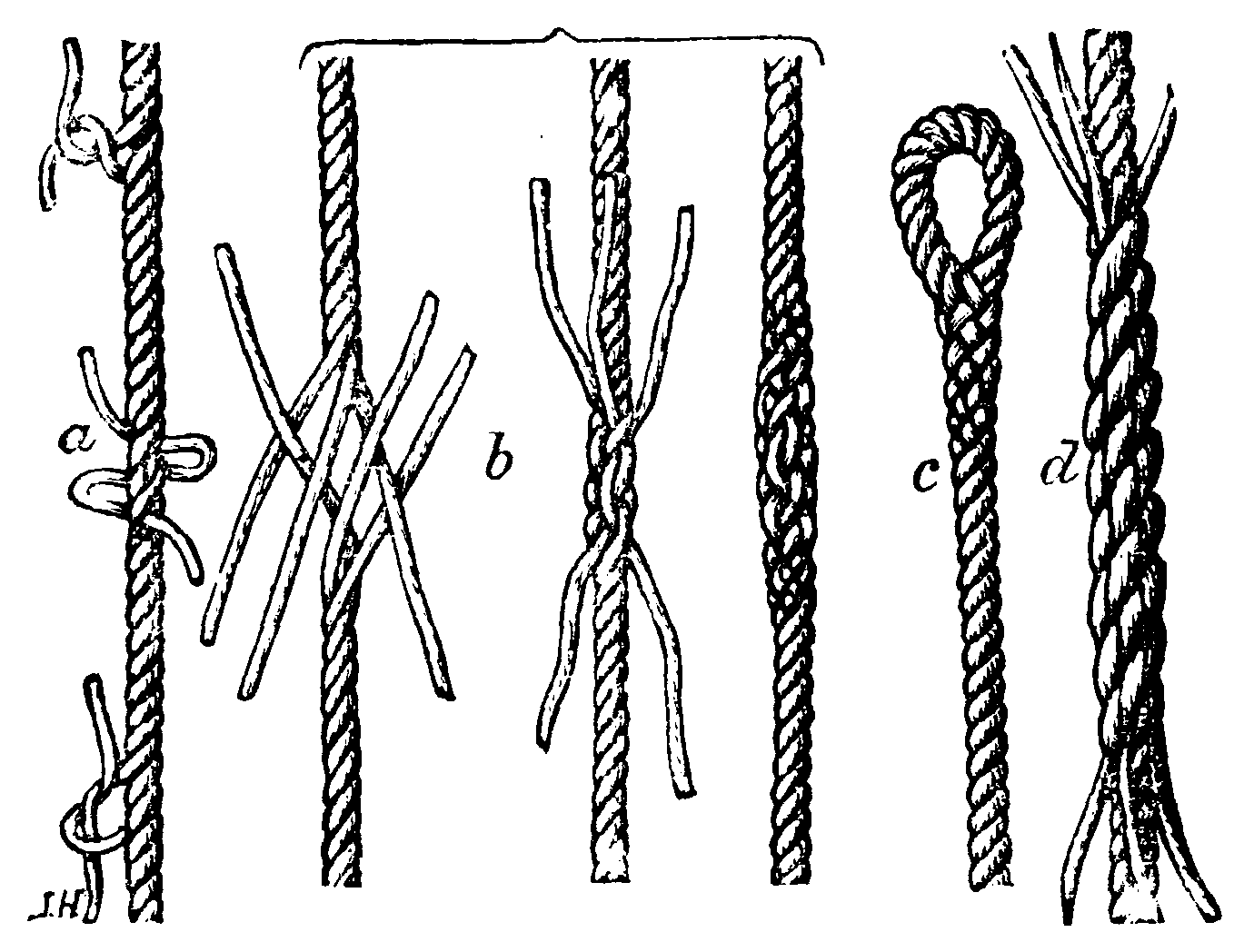

I’ll second BC’s comment, i’m 99% sure there’s not a welding spot in the whole cable, and the whole splicing holds together because of the torsion of the cable. You can try this at home with a 3 strand cotton cord, undo the strands of both ends, and start twisting two strands from one end around one strand from the other end. it works, but in order to make it resistant, there’s one rule to follow: the extension of the splicing must be 1.200 times the diameter of the cable, according to this french documentary (skip to minute 14:10 to see the whole cable related stuff):

http://www.dailymotion.com/video/x6i3tw_construction-telecabine-du-roc-aux_tech